Once the project has been divided into tasks and resources assigned to those tasks, the next step is to determine the task durations. This may seem trivial, but its importance cannot be understated because these durations will be used to construct the project schedule.

Just like the tiny O-rings that brought down the space shuttle Challenger, one small underestimation can result in a chain reaction that the project can’t recover from. Therefore, project planning needs to make sure that enough time is assigned to each task.

The PMBOK

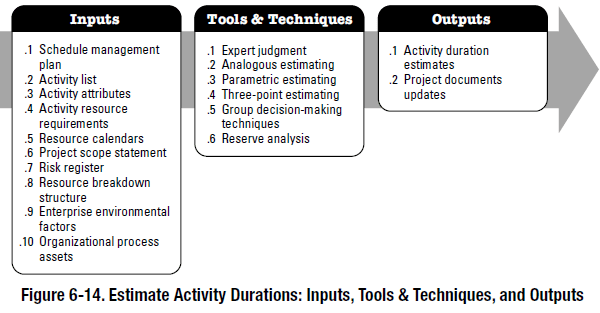

The PMBOK contains a process called “Estimate Activity Durations” which is part of the Project Time Management knowledge area. Like the other five processes involved in developing a project schedule, it falls within the planning process group.

PMBOK, 5th Edition, Section 6.5, “Estimate Activity Durations”

Estimate Activity Durations is the process of estimating the number of work periods needed to complete individual activities with estimated resources. The key benefit of this process is that it provides the amount of time each activity will take to complete, which is a major input into the Develop Schedule process.

The Inputs, Tools & Techniques, and Outputs are:

To determine the availability of resources, a project manager consults a document called a resource calendar. This states the availability of a resource, for example, “Mark is at jobsite X from Sep. 1 to Sep. 30.” Obviously, the new project being planned cannot use this worker at that time (unless arrangements are made with the other project manager, I suppose). The resource calendar can be as simple as a listing of workers’ availability, or it can be a calendar within project management software that tracks employees’ schedules.

Yesterday we listed the three main types of estimates. Today we will expand them, work through them, and add one more. The four types of estimates are:

- Analogous Estimating

- Parametric Estimating

- Three point Estimating

- Expert Judgment

Analogous Estimating

As the name suggests, this is when you make an analogy to the same, or similar, task that has been performed before. This is the best source of information because actual work completed is extremely reliable even if it needs adjustments. In fact, many project-based organizations have numerous similar projects, and this is the natural starting point. Here is a checklist of potential adjustments:

- The task is bigger or smaller than the last one.

In this case, scale the duration up or down by the appropriate amount. For example, the log house has slightly more square footage, or the driveway is longer, or several more windows have been added. This might sound obvious but it’s never the big, obvious things that cause problems for project managers, it’s the little things. You have to make sure you include enough contingencies for them. - The task needs specialty products or services that the previous one didn’t.

In this case, add in the appropriate products and services and proceed as usual. This also sounds obvious but has equally high potential for project overruns. For example, the slightly bigger roof trusses might require the next larger size of crane. Or the foundation requires removal of rock instead of clay. - The task is for a slightly different end product.

Determine the difference in materials and/or workmanship and figure out the difference in resources, cost, and time. For example, you could calculate from the plans that the log home requires 20% more timber than the previous one. Then you could estimate that the Wood Work task will take 20% more time.

One of the most problematic issues with analogous estimating is that it’s only as reliable as actual data the estimate is being taken from. Often you need to have been the project manager of the previous project, or at least close enough to it to know what happened and how it went. Say, for example the crane broke down and spent four days on site instead of two, you would not need to necessarily account for that in the new estimate. But it’s rarely obvious that something out of the ordinary happened after the fact.

Also, the productivity of the work is an important consideration. For knowledge workers such as engineers, adding more of them sometimes slows the production and decision making process down instead of speeding it up. Also, a very experienced laborer has higher productivity than a less experienced one. Thus, if the previous project used an inexperienced laborer to place the roof trusses, and this time you will be using a more experienced one, the estimate can and should be different.

Parametric Estimating

A second common method for estimating task durations requires that the work be drilled down into a unit cost, such as a construction time per square foot of log home. Here are some examples:

- Total construction time per square foot of log home.

- Pouring time per cubic yard of concrete.

- Installation time of carpet per square foot.

In the engineering industry almost everything is done this way, from the engineering time down to the construction materials. If the log home company kept track of the construction time, especially for the individual task of Wood Work together with the square footage of the home, they could eventually arrive at a pretty good parametric estimate for all of the task durations. In fact, a parametric estimate of the entire project would serve as an excellent double check (Cost or Duration per square foot of home).

If your company is project-based and has many similar projects, you need to make sure these parametric estimates are available and updated regularly.

Sometimes a parametric value includes fixed items, such as doors and windows which require a fixed time for installation regardless of how much timber there is to construct in the whole house. In this case the fixed items can be separated out and added to the overall parametric estimate.

Three-point Estimating

In this method, the estimator determines three numbers:

- Optimistic

- Most Likely

- Pessimistic

The second, “Most Likely” is the average of what the task duration would be if performed many times, in other words the normal estimate using other methods. The other two represent the upper and lower bounds that you are not likely to exceed.

To do this numerically you would assign a confident interval for the upper and lower bounds (optimistic and pessimistic values), such as 90%. Many textbooks use 99% or some other value, the methodology varies. But if you have 10 previous projects to consult from and can determine what value 1 out of 10 projects exceeded, you can run with that.

Generally one of two distributions is used. The triangular distribution is simply an average of the three estimates and the beta distribution is a bit tighter.

| Triangular (average) distribution | Beta distribution |

|---|---|

| te = (a + m + b) / 3 | te = (a + 4m + b) / 6 |

Where:

- te = Expected duration

- a = Optimistic

- m = Most likely

- b = Pessimistic

The triangular distribution will skew the results to the value which is farther away from the Most Likely value. The beta distribution also does that but tightens up the distribution (closer to the Most Likely value). I don’t believe there’s any more rocket science involved in this. You simply have to decide how tight to the Most Likely value you want to be.

For example, let’s say the expected duration of the task Wood Work is 18 days (m = 18), and you figure there is significant potential for delays. The Optimistic estimate is 15 days (a = 15), but the Pessimistic estimate is 33 days (b = 33). The beta distribution yields:

te = (15 + 4 x 18 + 33) / 6 = 20 days

To summarize, the original estimate was 18 days but because of the potential of reaching as high as 33 days, the estimate is increased to 20 days.

Let’s use some very simple statistics to determine the odds of exceeding 20 days. The standard deviation of the distribution is:

σte = (b – a) / 6

If you add up all of the durations (∑m) and standard deviations (∑σ) for each task, you will have the total project duration as well as it’s standard deviation. You can draw the following conclusions from this:

- The confidence level in one standard deviation, i.e. M ± σ is about 68%.

- The confidence level in two standard deviations, i.e. M ± σ is about 95%.

- The confidence level in two standard deviations, i.e. M ± σ is about 99.7%.

In the example above, for the Wood work task the standard deviation is (33 – 15) / 6 = 3.0. Therefore, the task duration is:

- 20 days is the official estimate.

- 23 days with 68% confidence.

- 26 days with 95% confidence.

- 29 days with 99.7% confidence.

Do you think your boss would love this?

Just don’t be fooled by fancy statistics that make the conclusion sound more reliable than the input data. In other words, garbage in, garbage out.

Expert Judgment

Professional estimators will tell you that in spite of all the techniques in the book a technical expert will be the best resource you could ever have. They could be the only resource you need for estimating. Technical experts are notoriously busy because their expertise gets used on many projects. But if you have access to one, whether inside the company or out, you should find a way to use them.

But what if a technical expert contradicts the other methods? For example, let’s say you’re installing carpet and your carpet installer tells you a certain project will take 4 days, but past experience (analagous) is telling your it will take 10 days. How valuable is the expert’s opinion then? It is difficult to give good advice that applies to all situations. You must simply weigh the two methods against each other, considering the underlying data of each method. For example, maybe this carpet installer frequently underestimates duration, or the past experience estimates are skewed by a certain piece of data.

Project management itself does not exist independent of the technical expertise inherent in the project. That is, the project manager or management team must be at least passingly familiar with the technical aspects of the work or the project has little chance of success.

Example Project

To build our log home, we would inspect each resource table from the previous step and determine the amount of time required.

In this case I have included contingencies of between 50% and 100%, because the duration needs to include downtime. For example, there might be 3 days of plumbing but the task needs to include the time before they arrive, potential time overruns, and final inspections.

| Task ID | Name | Durations | Cost |

|---|---|---|---|

| 110 | Excavation | 6 days | $5,850 |

| 120 | Pour Foundation | 10 days | $4,700 |

| 210 | Wood work | 20 days | $60,850 |

| 310 | Electrical & Plumbing | 10 days | $20,260 |

| 320 | Flooring | 8 days | $18,760 |

| 330 | Finishing | 12 days | $16,760 |

| 410 | Landscaping | 14 days | $7,620 |

| TOTAL | 80 days | $134,800 | |

The total of 80 days doesn’t mean much because it will still change. It will decrease because in the next step (schedule development) you will prioritize the tasks, putting some of them in parallel with others and smoothing resource usage to create the most efficient schedule.

Leave a Reply