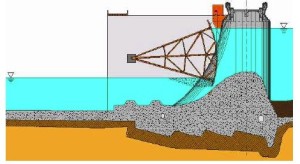

Radial Gates, also known as tainter gates (after the structural engineer who popularized them) are the most common type of spillway gate in use today. It is classified as an undershot gate because water flows under the gate. It consists of a curved skin plate supported by a structural steel frame. A hoist system is used to raise or lower the gate.

Advantages

- Better discharge characteristics than partial gate openings.

- Low cost.

- Bearings are located out of the water.

- Aesthetics – Does not require an overhead supporting structure (gate tower).

- Does not require gate slots which can become plugged with ice or debris and can cause cavitation.

Disadvantages

- Longer piers.

- Relatively high concentrated loads at the trunnions.

- More complex fabrication than other gate options.

- More complicated dogging system to facilitate maintenance activities.

Parts

Radial gates consist of the following four parts:

- The gate leaf assembly, including the curved skin plate, cross bracing or struts, supporting beams and girders, and rubber seals.

- Arm assembly, including the arm columns, bracing, and hub.

- Trunnion assembly, including a pin, busing, thrust washers, lubrication provisions, and yoke.

- Trunnion support assembly, including the trunnion beam or anchor block and anchorage system.

- Wire rope hoist system.

Structural Design

Structural Design

In a radial gate, water pressure is transferred from the curved face to the radial gate arms which transfer the load to a common bearing on either side of the gate opening.

Load combinations for water control gates can be complex and special care should be taken in identifying all of the important combinations. Agencies will usually provide guidance (or rigid codes) on this but I will present here some of the most important ones:

- Dead Load + Impact (during installation, dry testing, or servicing)

- Dead Load + wave load

- Dead Load + Hydrostatic Load corresponding to top of gate

- Dead Load + Hydrostatic Load at design flow level + Ice load

- Dead Load + Hydrostatic Load at spillway design flow (gates open)

- Dead Load + Hydrostatic Load at design flow level + Earthquake force

- Dead Load + Hydrostatic Load at Inflow Design Flow with gates open.

Hydraulic Design

Hydraulically, the gate is a sluice gate and should be designed as such. You use the Bernoulli equation to equate the energy on both sides of the gate, which eventually results in:

v1(b1·h1) = v2(b2·h2)

Where:

v1 = upstream velocity (m/s or ft/s)

A1 = upstream flow area (m2 or ft2)

b1 = upstream flow width (m or ft)

h1 = upstream flow height (m or ft)

v2 = downstream velocity (m/s or ft/s)

A2 = downstream flow area (m2 or ft2)

b2 = downstream flow width (m or ft)

h2 = downstream flow height (m or ft)

This results in the downstream flow depth and velocity (b2 and h2), which you would use in the spillway or canal design.

tauqir ahmad qureshi says

tauqir ahmad qureshi says

July 16, 2014 at 10:28 ami want design calculations of radial gate design

Shahbaz Hassan says

Shahbaz Hassan says

December 19, 2014 at 12:20 amdesign a radial gate is as follows

1. DESIGN CONDITIONS

Design Conditions

2. DESIGN LOAD

– Normal design condition

– OBE condition

– MCE condition

– Design Hydraulic Pressure

3. STRENGTH CALCULATIONS UNDER NORMAL CONDITION

– Auxiliary horizontal beams

– Beam arrangement and design hydraulic pressures

– Strength of auxiliary horizontal beams

– Skin plate

– Bending stresses

– Correction factor

– Hydraulic load acting on skin plate

– Stresses acting on skin plate

– Main vertical beams

– Loads

– Bending moment and shearing force

– Sectional modulus and stresses

– Main framework

– Loads acting on main frameworks

– Arrangement of main vertical beams and arms

– Section properties of horizontal connection beams

– Sectional properties of arm

– Frameworks

– Stresses of frameworks

– buckling and stability of buckling

– Trunnion assemblies

– Trunnion pins

– Trunnion bearing

– Bracket

– Hoist System

– Operation load

– Hydraulic cylinder

4. STRENGTH CALCULATION UNDER MCE

– Auxiliary horizontal beams

– Beam arrangement and design hydraulic pressures

– Strength of auxiliary horizontal beams

– Skinplate

– Bending stresses

– Correction factor

– Hydraulic loads acting on skinplate

– Stresses acting on skinplate

– Main vertical beams

– Loads

– Bending moment and shear force

– Sectional modulus and stresses

– Main framework

– Loads acting on main frameworks

– Arrangement of main vertical beams and arms

– Section properties of horizontal connection beams

– Sectional properties of arms

– Frameworks

– Stresses of frameworks

– Check of whole buckling and stability to buckling

– Trunnion assemblies

– Trunnion pins

– Trunnion bearing

– Bracket

Muhammad Saqib says

Muhammad Saqib says

July 11, 2015 at 12:35 amDear,

please tell me any best book related to designing of hydraulic gates.im using “design of hydraulic gates by erbistri”.if u know any better book please tell me.

M Debnath says

M Debnath says

November 30, 2016 at 9:54 pmthere is no better book other than “design of hydraulic gates” by Paulo F Erbistri

Vinod kumar gupta says

Vinod kumar gupta says

May 18, 2019 at 5:55 amOne more book by Jack Lewin can also be seen

gamini ranaweera says

gamini ranaweera says

December 16, 2015 at 3:47 amI am a mechanical engineer attached to a Sri Lankan company engaged in heavy fabrications. Recently we have been entrusted with fabrication of a radial gate of a dam. It’s merely a copying and replacing job. To my academic interest I thought of checking the design by calculating. I came across your article which was very useful. Can you kindly explain what is OBE and MCE condition? Further can you recommend a syitable book to guide me on structural calculations?

Thanking you.

Gamini

Asela says

Asela says

July 29, 2016 at 8:04 pmHi,

This is very interesting. Can you share the design calculations?

Asela

Mokgadi Sathekge says

Mokgadi Sathekge says

February 16, 2017 at 3:53 amhi i need help regarding refurbishment of radial gates

Umakant patel says

Umakant patel says

January 19, 2015 at 7:05 amIf vertical hydrostatic force is more than dead weight of gate when gate at sill level and water is at full level , is there is a self closing problem ?.

Dinesh Chaudhari says

Dinesh Chaudhari says

April 2, 2015 at 11:48 pmI wanna degine service gate, Who i can degine it ? Would you like to hell me ?

R.Suthar says

R.Suthar says

October 30, 2015 at 11:41 ami want to Design Dial Indicator for Radial Gate

Ogie Umipig says

Ogie Umipig says

November 23, 2015 at 9:47 pmSir

i need sample on sizing up the hydraulic cylinder of a radial gate

height of gate= 3,477 mm

width of gates= 2,812

Radius of gates= 3,750 mm

weight of gates only = 3,488 kg

operating pressure= 1,500 psi

i need to get the proper size of cylinder and the flow requirement of the hydraulic pump can you please help me.this is intended for sluice way

regards