Performing quality assurance ensures that the processes are in place to produce the project deliverables at the applicable level of quality. Normally called QA, it is the process of auditing and analyzing the systems which produce a product in order to improve their quality.

It should not be confused with Quality Control, which is a direct measurement of the deliverables to ascertain the quality of one batch.

In the Project Management Body of Knowledge (PMBOK), Quality Assurance is part of the Executing process group and is performed throughout the duration of the project.

PMBOK, 5th Edition, Sction 8.2, “Perform Quality Assurance”

Perform Quality Assurance is the process of auditing the quality requirements and the results from quality control measurements to ensure that appropriate quality standards and operational definitions are used. The key benefit of this process is that it facilitates the improvement of quality processes.

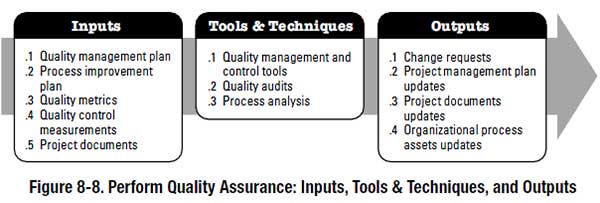

The full process description looks like this:

According to the PMBOK, the project management plan should have a component called a Quality Management Plan which is dedicated to project quality. The Quality Management Plan contains the Quality metrics which will be used to judge the pass/fail criteria, and both of these are inputs into the process. The Quality Control measurements themselves also become an input, as the actual quality data is important to assess the processes at work in producing them.

When quality assurance activities identify a quality problem which leads to project changes, the project management plan may need to be updated.

A project manager might investigate a quality problem, such as “the legs of the couch are prone to break during shipping” and make changes to the production process. Whether the solution is to strengthen the legs (various options to do this), changing the location within the package, or changing the shipping methods, the work that is involved falls under the category of quality assurance. Throughout the development project the project manager must perform “quality audits” which range from basic internal inspections to external consultant audits, with the goal of identifying the major quality issues.

Quality Assurance asks the following questions:

- What are the applicable quality standards?

- How will quality be measured?

- Who will measure it?

- What will be measured? (i.e. How many units? Which types? Which processes?)

- When will it be measured?

- What is the criteria for rejection?

Quality Assurance vs. Quality Control

This is a frequent source of confusion.

- Quality assurance creates the systems to measure and control quality, in order to create confidence that quality products will be produced.

- Quality control measures the quality level of individual products/deliverables, and accepts/rejects them based on the criteria developed by quality assurance.

If you’re measuring the outputs, it’s QC. If you’re measuring the process, it’s QA.

Quality Control Data is an input into the Quality Assurance process, since the processes to measure quality might need to change to provide better assurance of quality.

Quality Assurance Audits

Quality systems should be consistently audited to ensure the processes being used are producing quality products. These audits involve:

- Analyzing quality control data to determine if quality problems exist (and revising the minimum quality standards if necessary).

- Identifying process improvements that will increase quality.

- Performing root cause analysis to determine necessary improvements.

- Determining preventative actions to deter future quality issues.

The project management team should always be on the lookout for improvements to the processes being used. The root causes can often be difficult to determine, so it is important to perform the necessary background research.

Developing preventative actions is often one of the best ways to develop confidence in the quality of the deliverables. Stakeholders who see consistently high product quality will gain confidence and allow a bit of breathing room when a quality issue occurs.

A quality audit can compare quality control data with other projects within the organization to see how the project is doing relative to previous projects.

They can also be shared with clients and/or project sponsors.

Continuous Improvement

In spite of the implication of one-time improvements by performing quality audits, the real goal is continuous improvement. It is important to ensure that improvements are constantly on the mind not just of the project management team, but the project team on the ground as well.

Many organizations operate on the principle of Kaizen, a system of continuous improvement. This philosophy attempts to empower front line workers to make continuous improvements in the processes they use daily. It is not focused on major improvements. Rather, employees are encouraged to submit small, minor improvements to their managers anytime they are encountered. Management is empowered to stop production to make the changes. Management is also encouraged, even judged, on the number of improvements suggested by their business unit. The more, the better. In many businesses, suggesting process improvements is seen as bad because you are exposing problems in the business unit. Therefore, Kaizen is a system of cultural focus on continuous improvement.

Quality Assurance Tools

When you’re analyzing a process with the intent of making improvements, there are usually many factors with complex relationships between them. Interrelated causes and effects can be difficult to understand and sort out. There are seven primary tools in the quality assurance professional’s toolkit.

- Affinity diagrams

These are effective in reducing the group bias when brainstorming. Instead of one facilitator or dominant group member leading the group to one conclusion, the group develops ideas individually and then collectively organizes them into categories for further analysis. - Process decision program charts

A structured method for determining risks and response plans. It is a good method of determining necessary contingencies. Level one contains a task or process, level two contains all of the potential risks to that process, and level three contains the response plans for those risks. - Interrelationship diagrams

These are used to flush out the primary causal factors when there are many, interrelated factors. A problem statement is generated, such as “The handle on the widget breaks too easily.” Then all of the relevant factors are written down in a circle and teams identify which factors are in a cause-effect relationship with other factors, drawing an arrow for each one. The factors which contain most of the arrow handles are the primary causes of the problem. - Tree diagrams

Useful for visualizing the parent-child relationships between tasks or processes. When there are a limited number of dependent relationships, writing out a tree diagram can flush out the primary causes of a defective product. - Prioritization matrices

These represent a good way to isolate the best course of action when multiple issues are present. They consist of ranking each issue on a scale of 1-10 (or similar) for specific criteria, like frequency of occurence, feasibility, and customer benefit. The results are added together to obtain a score which can be used to make a decision to move forward with an improvement. - Network diagrams

The activity network diagrams are very helpful to determine what the existing processes are and how they interact with each other, which can be important to understand the potential improvements and what changes they will bring. - Matrix diagrams

A generic form of diagram that can be used to identify the relationships between factors, causes, and objectives. They can be 2 or 3 dimensional in that they can be shaped like an L, T, Y, C, or X.

Leave a Reply