Lean manufacturing transformed the manufacturing world during the 2000’s.

Invented in Japan, where there are neither natural resources nor excess space for production, manufacturing needed to be lean, mean, and efficient to provide value. In turn, the success of japanese manufacturing resulted in an explosion of interest from around the world. The Toyota Production System is largely considered the precursor to Lean Manufacturing.

Lean manufacturing truly turns some of the traditional manufacturing concepts on its head.

But more than just a defined method of process improvement, it is a method of organizational transformation.

Lean Manufacturing is broken down into five core principles:

- Value

- The Value Stream

- Flow

- Pull

- Continuous Improvement

Value

Firstly, lean manufacturing gets right down to the basics.

There is one critical variable that defines all business: value. Value is defined as the amount that someone is willing to pay for something, and it is this, and only this, that allows any business to function. More specifically, when a person or organization desires a product or service that it is willing to pay for, value is created. It is this desire to exchange monetary resources with a product or service that creates value.

Thus, defining this value is the first step in lean manufacturing. Lean thinking must start with a conscious attempt to precisely define value in terms of specific products with specific capabilities offered at specific prices through a dialogue with specific customers.

Thus, defining this value is the first step in lean manufacturing. Lean thinking must start with a conscious attempt to precisely define value in terms of specific products with specific capabilities offered at specific prices through a dialogue with specific customers.

In defining this value, the lean manufacturer must define:

- What product will satisfy the customer’s need?

- What features will it have?

- What quality level must it have?

- What price will they pay?

- How will they use the product?

- What maintenance requirements does it have?

- Any other item which is part of the definition of value by the customer.

For example, the value proposition for a furniture manufacturing company is to sell furniture at a fair price, without defects, that lasts for 10 years under heavy use.

The Value Stream

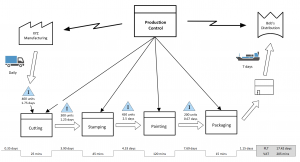

Once the value has been defined from the customer’s perspective, the steps required to create that value are identified. Each major step in the process is itemized and charted. Usually there are multiple, parallel production lines that converge into one step (like packaging).

Value stream mapping analyzes the flow of materials and information through the production process, from raw materials to finished product. It is a visualization of the value stream, from the start of the production process to the customer. For example,

A full value stream map would include many more pieces of information.

The processes are not all within the internal plant. Lean manufacturing looks at the entire value stream which normally includes suppliers and contractors as well as the internal operations.

Flow

In a traditionally (non-lean) plant, manufacturing takes the form of a batch-and-queue system where there are different stations for different types of work. For example, in a bicycle production plant, there would be a station for tube cutting, another station for frame welding, and another for painting. Each station performs its work in batches, that is, a certain number of a kind of bicycle is needed, followed by a changeover (including downtime) to the next type or variation. The larger the batches the better, because the goal is to minimize the downtime of expensive machinery and people.

In contrast, a lean manufacturing facility seeks to minimize the inventory waiting time rather than machinery downtime. Since the material on the assembly line represents value, putting into the customer’s hands, and therefore money in the bank, at the fastest pace is the focus rather than keeping a machine running constantly. The inventory waiting time is considered a waste (muda) that should be reduced or eliminated.

In contrast, a lean manufacturing facility seeks to minimize the inventory waiting time rather than machinery downtime. Since the material on the assembly line represents value, putting into the customer’s hands, and therefore money in the bank, at the fastest pace is the focus rather than keeping a machine running constantly. The inventory waiting time is considered a waste (muda) that should be reduced or eliminated.

Hence, the goal is to produce continually from one production station to the next without any stoppage in inventory between stations.

- The product does not stop between production stations.

- Each station within the production line must have the same processing time, called takt time. Some stations will need to divide out into 2, 3, or more stations to achieve the same takt time.

- To increase production, create an identical, parallel production line.

The results are:

- You don’t need to pay for all of the raw materials right away

- You don’t need space to store all of the inventory

- You can deliver the finished product to the customer faster

- If the customer wants to change something, it can be done without extensive rework.

The time from raw material to finished good is often reduced by 90% or more versus non-lean manufacturing. As a result, it is easy to accept orders from a customer and give them a finished product in their hand in hours or days instead of months, allowing them to provide feedback. Then, the feedback can be quickly incorporated into the production via fast equipment changeovers.

Pull

Traditional manufacturing works largely on a “push” system. The factory would like to sell a certain type of product, therefore the salespeople need to get to work selling it. The plant needs to produce a significant number of “extra” finished products to ensure they can fulfill urgent orders immediately, and many of them end up being wasted. The various types and models are estimated in the largest possible batch sizes so that changeovers are minimized.

In contrast, lean manufacturing works the opposite, on a “pull” system. That is, the assembly line does not get to work until a customer orders the product.

In contrast, lean manufacturing works the opposite, on a “pull” system. That is, the assembly line does not get to work until a customer orders the product.

In addition, the speed of the assembly line is meticulously controlled to produce just the right amount of product in accordance with demand. For example, if the demand is anticipated to be 50 bicycles per week, the assembly line is created so as to create exactly that number. Remember, waiting for the next assembly station is muda, and waiting for finished products to be sold is also muda. Both are wasteful.

The speed of the assembly line is called takt time, and it is measured in units of time (minutes, hours, days) per production station. In a very general sense, if the slowest station on an assembly line takes 25% longer than the next station, each product will spend 25% more time on the assembly line than if that station were removed. Takt time is the concept of aligning each station in the plant to one, single processing time (or half, third, double, triple, etc.). This also is aligned with the demand for the product.

The pull system is managed using a system called kanban. When an order is received, a kanban card is created for the finished product. The card contains a tracking item for each step in the manufacturing process and moves with the product until it is completed. No kanban card, no production.

Continuous Improvement

As you can see, lean manufacturing seeks to establish an assembly process where the raw materials become the final product without ever waiting. They are constantly moving through the process, and the minimal amount of parts are stored. The customer orders a product, the assembly line is re-tooled, and the first product is ready quickly. Of course, most products need to be shipped in batches (shipping one pencil at a time would be uneconomical). Because of this, and the natural variations in production efficiencies that cause a variation in takt time, minimum inventories of parts need to be maintained at various steps in the process. Hence, the next step is continuous improvement, called kaizen.

Kaizen seeks to continually optimize the assembly line via the relentless elimination of muda (waste).

The original architect of the Toyota Production System, Taiichi Ohno, did not merely talk about the reduction of waste, he specified the total elimination of waste from the manufacturing process. Getting rid of all muda should be ruthless. When muda is discovered it should be eliminated immediately, by the production floor personnel if possible, without planning meetings and deliberations. The patient is sick and the situation is an emergency.

The original architect of the Toyota Production System, Taiichi Ohno, did not merely talk about the reduction of waste, he specified the total elimination of waste from the manufacturing process. Getting rid of all muda should be ruthless. When muda is discovered it should be eliminated immediately, by the production floor personnel if possible, without planning meetings and deliberations. The patient is sick and the situation is an emergency.

To that end, there are 7 types of muda (waste) in lean manufacturing:

- Overproduction is the production of finished goods that are not sold, or must be stored for long periods of time.

- Waiting is the product waiting for the next assembly station, workers waiting for the previous station for complete, or waiting due to machinery failure.

- Transportation is the movement of parts around the plant.

- Overprocessing is the processing of a product beyond what the customer wants.

- Movement is the movement of people, such as operators looking for tools, equipment or parts.

- Inventory is the the storage of raw materials that is not being produced into finished products. This has coined the term just-in-time manufacturing.

- Making defective parts is the production of products that are scrapped. The entire assembly line has been wasted in the production of scrap products.

Modern Lean Manufacturing adds one more muda:

- Unused skills is the knowledge and skills that the plant’s personnel have that are not being used to improve the product or reduce muda.

The concept of continuous improvement (kaizen) seeks to continuously inspect the production process for signs of these eight muda and eliminate them from the system.

Lean Manufacturing Example

You need to mail a group of christmas cards.

Traditional thinking would have you setting up “stations,” organized by work type:

- Write out the card

- Put the card in the envelope

- Seal and address the envelope

You would perform each task on all of the envelopes, then move on to the next task.

In contrast, lean manufacturing would perform all of the tasks in sequence on one envelope, then move on to the next one.

Lean Manufacturing Certification

Unlike project management, there is no central body of knowledge and certification process for lean manufacturing. The Lean Enterprise Institute (LEI) is largely considered the leader in lean manufacturing but certification is generally obtained through either the AME or the SME.

- The Association for Manufacturing Excellence (AME) offers a three level (bronze, silver, and gold) certification scheme which is highly recognized in the manufacturing industry.

- The Society of Manufacturing Engineers (SME) offers a similar structure and can be completed entirely online.

- The Lean Enterprise Institute (LEI) maintains various training options but does not offer certification.

Lean Thinking

Although Lean manufacturing is a well defined process with well defined implementation steps, it is difficult to execute without changing the mindset of the workers performing it. That is, it is a culture more than a process of steps.

For this reason you will often find the term lean manufacturing used together with “lean thinking” or “organizational transformation.”

Lean Six Sigma

Although Lean Six Sigma is not an official methodology, there is a modest (and growing) body of knowledge related to it. Since lean and six sigma are both focused on manufacturing, the application of both methodologies simultaneously has some compelling rationale. Whereas lean manufacturing focuses on improving the production process, six sigma concentrates on the quality of the process’ outputs, triggering process improvements in response to product quality issues.

Lean Project Management

A project has one, or a few, outputs rather than a continuous stream as in manufacturing. That being said, a project has some compelling similarities to manufacturing in that it contains a defined production process that must be optimized for project success. That’s where the concepts of lean manufacturing can be utilized by project managers to achieve their project success factors, like finishing on schedule and under budget.

Leave a Reply